1. The fixed foundation cage ensures that the horizontal planes of the solar street light cage foundation and the base are consistent, that is, on the basis of two directions, one is horizontal and perpendicular to the top of the measured, and the pouring part is monitored. The extremely buried foundation concrete must be dense to prevent air bubbles in the concrete.

2. Plastic pipe paper or seals are used in the pre-embedded pipe mouth to prevent the concrete pouring from concrete to the structure of other materials embedded in the pipe, and the embedded pipe is blocked; after the foundation surface is poured, the foundation must be 5-10 higher than the ground Mm; concrete curing period to ensure that the concrete installation reaches a certain strength.

3. The street lamp pole must be grounded, and the grounding resistance is less than 5 ohms; each pole is determined according to the specific data of the site and the construction needs.

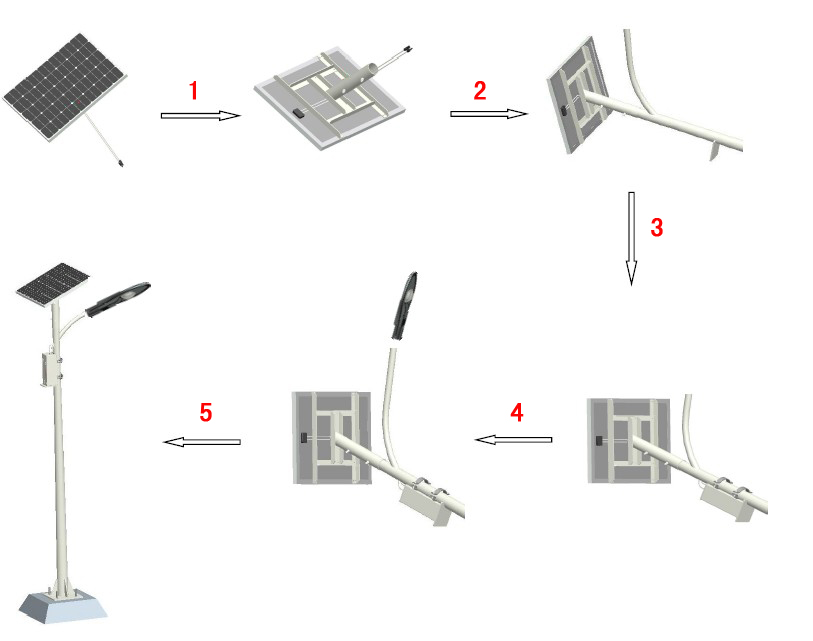

4. Installation requirements:

The installation is firm;Is perpendicular to the center line of the image plane; the 180° angle connection from the image center of the street lamp pole to the two slots should be parallel to the road; technical data should be measured on site to estimate the quantity. First lay the C20 concrete cushion to lay the trench cable, backfill with fine sand, and then restore the road according to the actual situation. Street lamp poles are made of galvanized steel; exposed cables (excluding overhead) are protected by galvanized steel.

After the installation of the solar street light is completed, check the installation effect of the overall street light, and readjust if the pole is tilted,check and confirm that there is no error before sub-testing can be carried out, and the commissioning record should be made.

Post time: Dec-24-2021